We often marvel at the shock that Hollywood blockbusters bring to us with their fake and fake special effects, and also admire the sense of security that Tesla's autonomous driving technology is increasingly improving and bringing to passengers. We are often amazed by the Meta's breakthrough AR technology that integrates surreal virtual environments into life, similar to that of Player One... These seemingly unrelated but equally significant technologies that drive the world's technological progress are all based on the same working principle: camera calibration.

Perhaps you have heard of it, perhaps you have never heard of it before. Today, let's analyze from a professional perspective what "camera calibration" is, which has been applied in countless fields and brought us countless surprises!!!

Camera calibration

What is "camera calibration"?

Official Encyclopedia Explanation: In the process of image measurement and machine vision applications, in order to determine the relationship between the position of a certain point on the surface of a spatial object and its corresponding point in the image, a geometric model of camera imaging must be established. The process of solving the relevant parameters of the geometric model is called camera calibration.

Simply put, the scene we live in is three-dimensional and three-dimensional, and what the camera captures is two-dimensional and flat. Compared to 3D, 2D lacks important information such as distance/depth. To obtain the original position and shape of an object in 3D from 2D images, a series of complex algorithms are needed to achieve this goal. The overall process of this algorithm is called phase calibration.

Realize

How to achieve "camera calibration"?

Speaking of camera calibration, let's use an example to illustrate it.

"Manhole imaging"

It involves five things: people (themselves), holes, light, walls, and portraits.

A person stands, and the light passes through the hole, shining upside down on the wall. The size of the portrait illuminated on the wall is determined by the distance between the wall and the hole.

If a "person" is located in the real world/three-dimensional world, under the illumination of light, and appears on the "wall"/two-dimensional world through the mapping of "holes", forming a "portrait", how can we know the true form/three-dimensional form of a "person" through the "portrait" on the "wall".

*Manhole Imaging · Model

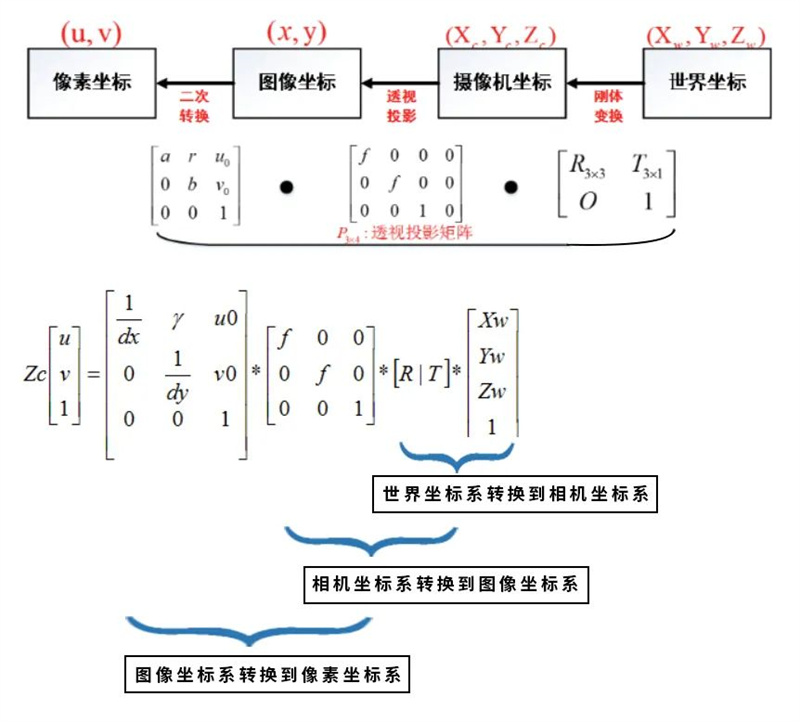

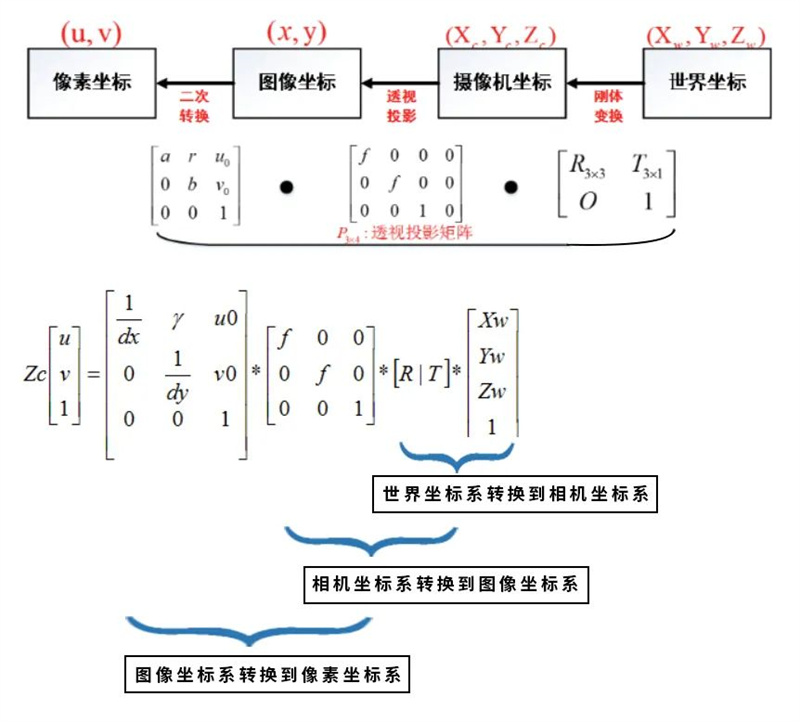

In camera calibration, "four coordinate systems" were used: world coordinate system Ow (Xw, Yw, Zw), camera coordinate system Oc (Xc, Yc, Zc), image coordinate system o (x, y), and pixel coordinate system Ouv (u, v). Through meticulous scientific algorithms, the relationship between the two-dimensional world and the three-dimensional world, namely the relationship between the pixel coordinate system and the world coordinate system, was obtained.

*Camera calibration · illustration

To achieve precision from the world coordinate system to the pixel coordinate system, it becomes a mutual conversion between four coordinate systems, which involves more professional knowledge. Let's continue to use the example of "manhole imaging" to explain from a simple perspective: if the position of a person standing (foot root) is taken as the origin of the world coordinate system, then the position of the "person" to the "hole" can be achieved through translation and rotation to achieve consistent direction and distance. We use R for rotation and T for translation; The distance from the "hole" to the "portrait" is Z, which is called "focal length" in imaging, and f represents the specific distance/focal length.

Finally, through layer by layer transformation, the relationship from the world coordinate system to the pixel coordinate system is:

The process from the world coordinate system to the pixel coordinate system

Did you just finish it so easily?

Of course not!!!

In the process of "manhole imaging", due to the size/distance relationship between "holes" and "people"; The "human image" formed through the "hole" often has some slight deformation, which we call "distortion". But "holes" are often centrally symmetrical, so "distortions" are also mostly radially symmetrical, which we call "radial distortions". "radial distortions" are generally divided into two types: pillow shaped and barrel shaped.

*Radial Distortion · Diagram

During the imaging process, if the lens and the imaging plane are not strictly parallel, it will cause tangential distortion.

*Tangential Distortion · Diagram

Since there is distortion, there is correction to complete the restoration.

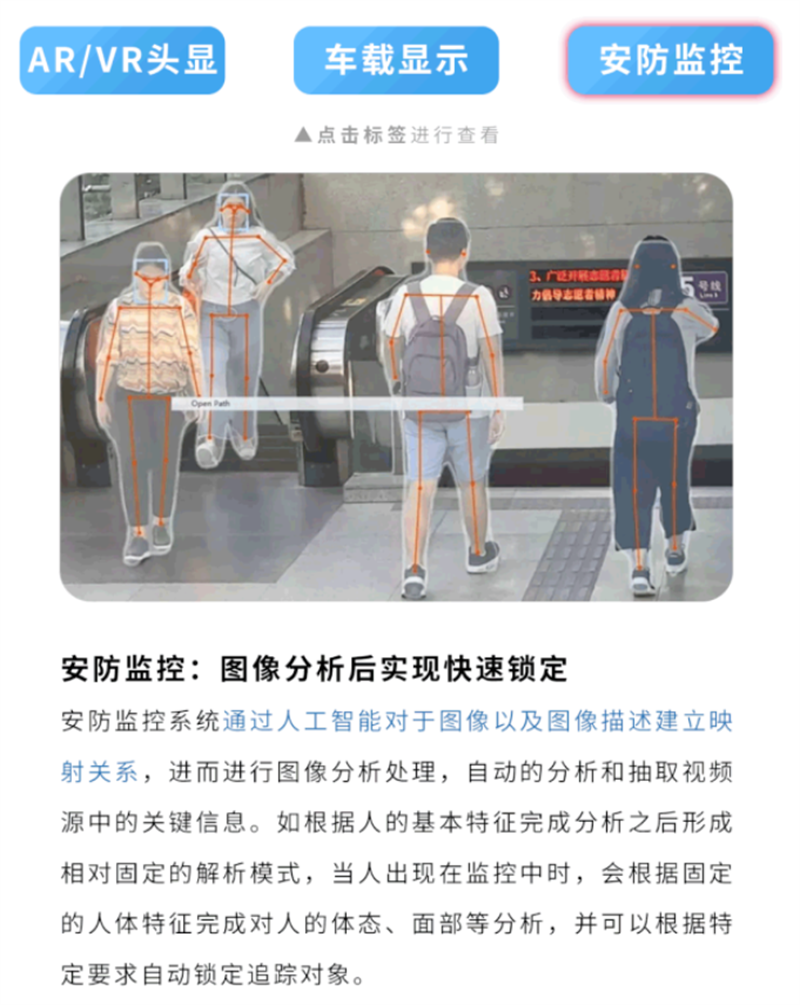

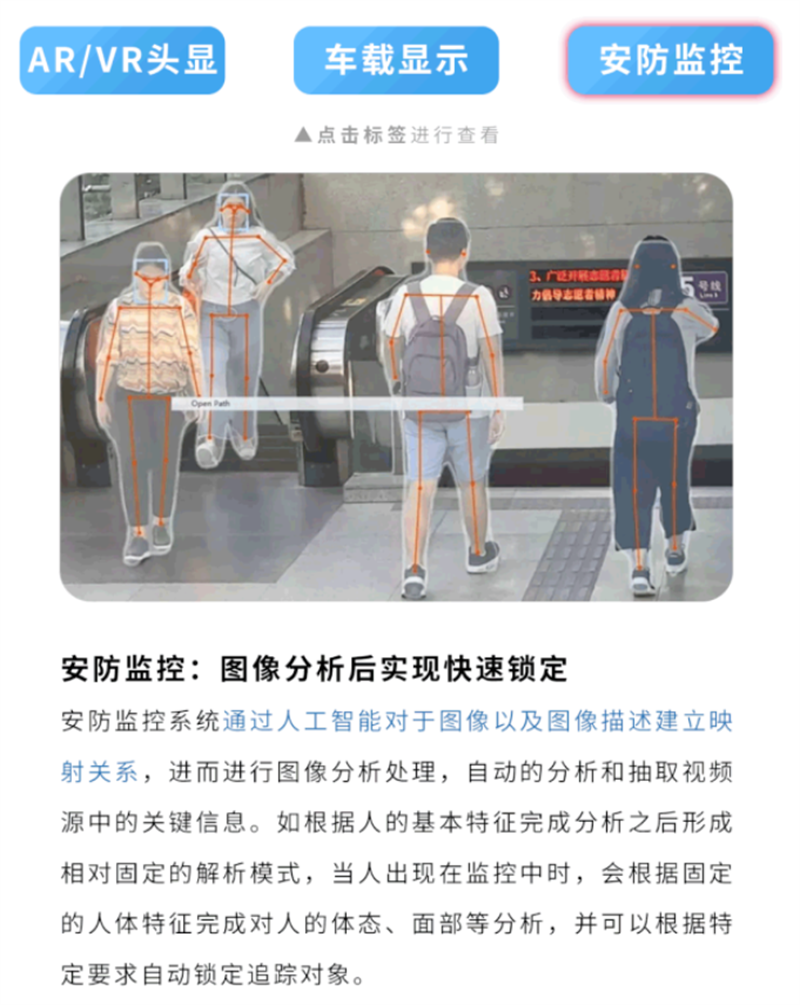

Through camera calibration, we can restore the true three-dimensional shape of objects from a plane, accurately determine the position information of objects in three-dimensional space, and enable three-dimensional objects to exist in two-dimensional form without losing all aspects of being three-dimensional objects... This helps us provide technical support in various scenes such as motion capture, three-dimensional modeling, positioning and navigation.

Scenario "Camera Calibration" for Scene Applications

In addition, there are many scenarios where this technology is used because its application scope is too broad, and more of it requires everyone to discover it on their own in daily life!!!

Cases

The "Camera Calibration" Application of Sixth Mirror Technology

As the sixth mirror technology committed to empowering traditional industries with AI technology for digital transformation, relying on self-developed algorithms and software and hardware integration, it has cooperated with multiple well-known enterprises to complete multiple solutions such as "hot rail defect detection", "digital coal bin", and "furnace roll nodule detection instrument", helping enterprises greatly improve production efficiency in their development process. The application of "camera calibration" technology has played a significant role in this.

*Sixth Mirror Technology's "Hot Rail" · 3D Image 1

*Sixth Mirror Technology's "Hot Rail" · 3D Image 2

*Sixth Mirror Technology's "Hot Rail" · 3D Image 1

For example, in the cooperation with Handan Iron and Steel Group's "Hot Rail Defect Detection", for the implementation of the entire process, Sixth Mirror Technology has developed multiple algorithms for "input" and "output" and applied them to camera calibration to achieve the optimal output for "Hot Rail Defect Detection". After generating a calibration plate contour model, the collected contour is inputted, and driven by the algorithm, the camera will perform affine transformation registration with the standard model to obtain calibration results. The data is then concatenated and corrected, and the elliptical contour is fitted to solve the radius and distance between the cylinder, evaluate the optimal calibration, and output the optimal calibration result after completion.

*Sixth Mirror Technology's "Digital Coal Bunker" Exhibition

In addition, in the "Digital Coal Bunker" project jointly with Xuyang Group, Sixth Mirror Technology combines laser scanning and bucket wheel machine 3D positioning technology to perform 3D imaging on the coal bunker, forming layered and partitioned storage data. Based on the registration time and area of the stacking and retrieval materials, it provides a basis for importing subsequent coal entry data and mining data.

With the increasing proportion of technology application in practice, traditional industries have gradually entered a new journey, striving to seek greater breakthroughs in labor costs, time costs, safety, and other aspects, and truly achieve full "intelligent" development from traditional methods. Sixth Mirror Technology will also continue to forge ahead and work together with traditional industries on the path of "intelligence", leaving more brilliance.

Note: This article (including images) is a reprint, and the copyright of the article belongs to the original author. If there is any infringement, please contact us to delete it.