With the improvement of China's supporting infrastructure and the accumulation of technology and funds, the demand for industrial automation and intelligence using machine vision technology is widely increasing in various industries. Yiou Think Tank and Alibaba Cloud Accelerator jointly released an analysis of the current relatively mature and highly promising industrial sub sectors, and combined with technological pain points to gain insights into future application trends.

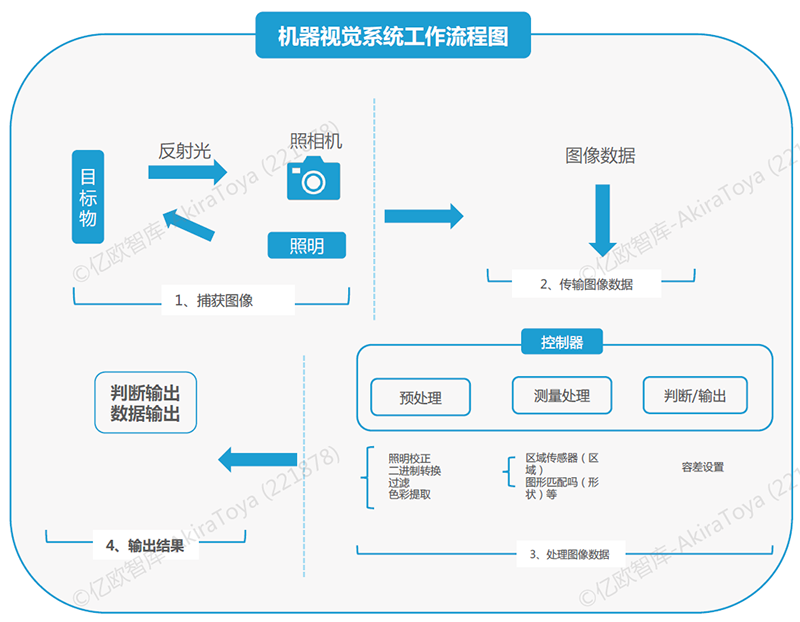

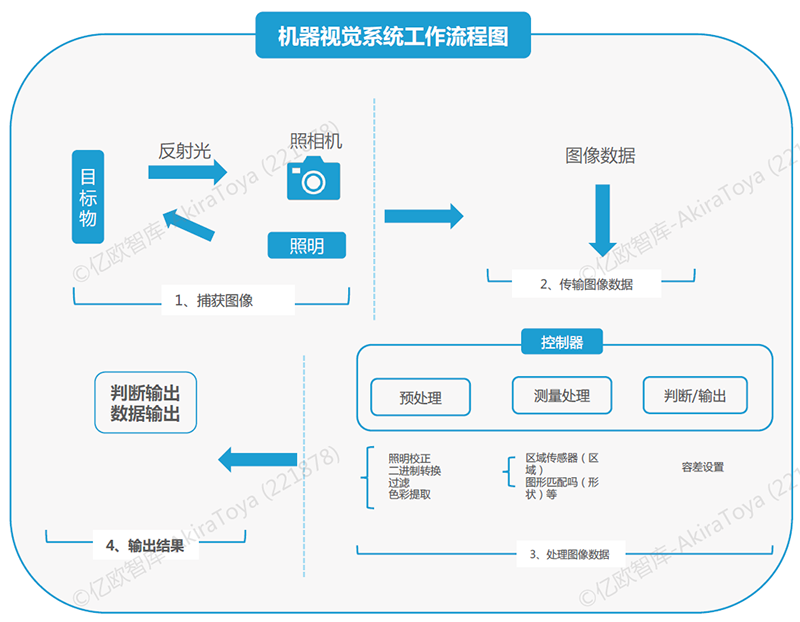

Machine vision is a rapidly developing branch of artificial intelligence that uses machines instead of the human eye for measurement and judgment. Through optical devices and non-contact sensors, it automatically receives and processes images of real objects to obtain the necessary information or to control the operation of robots. The core of industrial machine vision is to use the "machine eye" instead of the human eye to recognize, measure, and make judgments on objects.

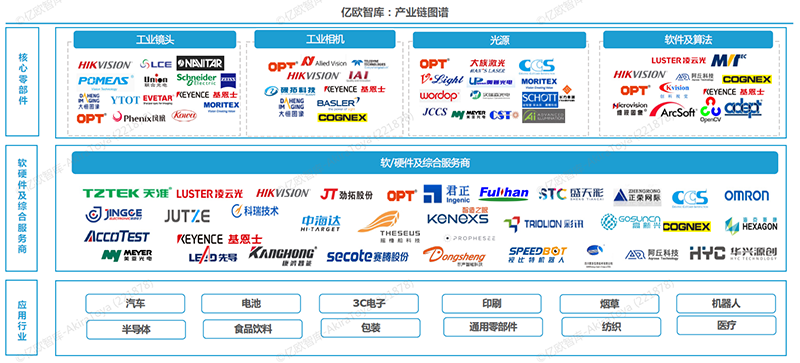

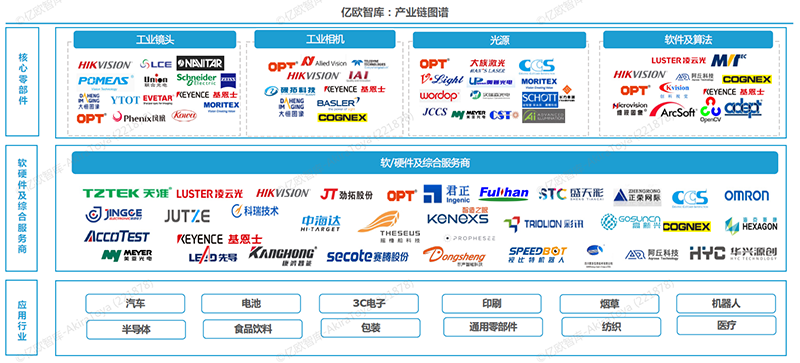

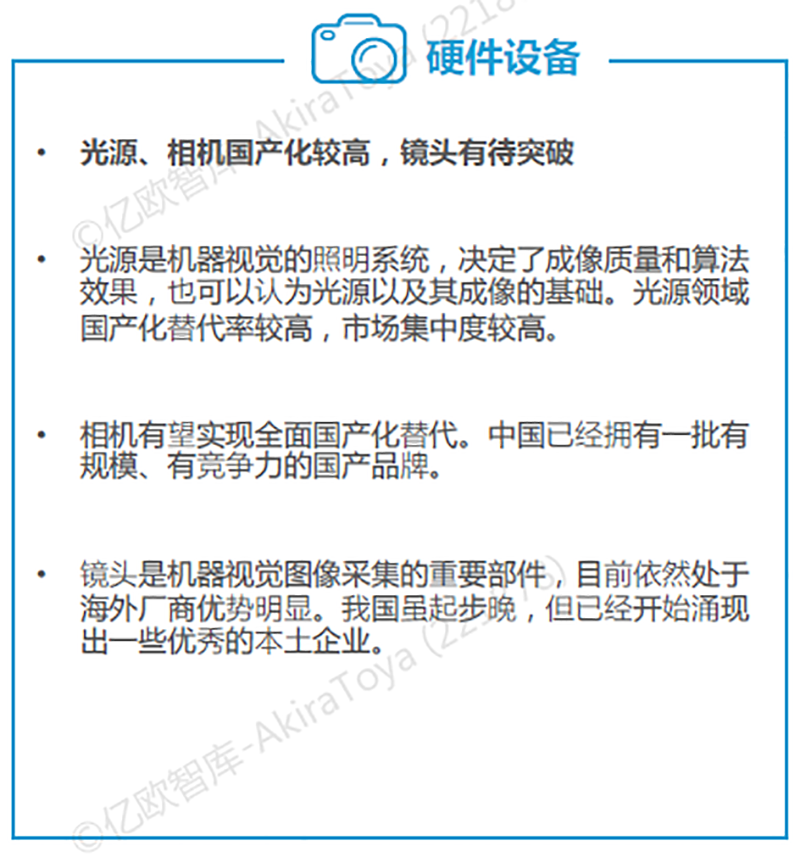

From the perspective of the machine vision industry chain, the links in the industry chain are relatively long. The upstream is composed of machine vision system hardware and software algorithms, while the midstream is mainly responsible for software secondary development and equipment manufacturing for equipment manufacturers and system integrators. The downstream application scenarios and industries are broad. Industry is currently the largest downstream application field in China's machine vision industry, accounting for 81.2% of sales in the industrial sector, including electronic manufacturing, display panels, automobiles, printing, semiconductors, food and beverage packaging, and other industries. Other industries such as transportation, entertainment, and national defense and security are auxiliary.

The Four Major Applications of Industrial Machine Vision

According to the research results of Yiou Think Tank, with the rapid development of industry depth and breadth applications, the four major tracks worth paying attention to in the field of industrial machine vision applications are 3C electronics, semiconductors, lithium batteries, and photovoltaics.

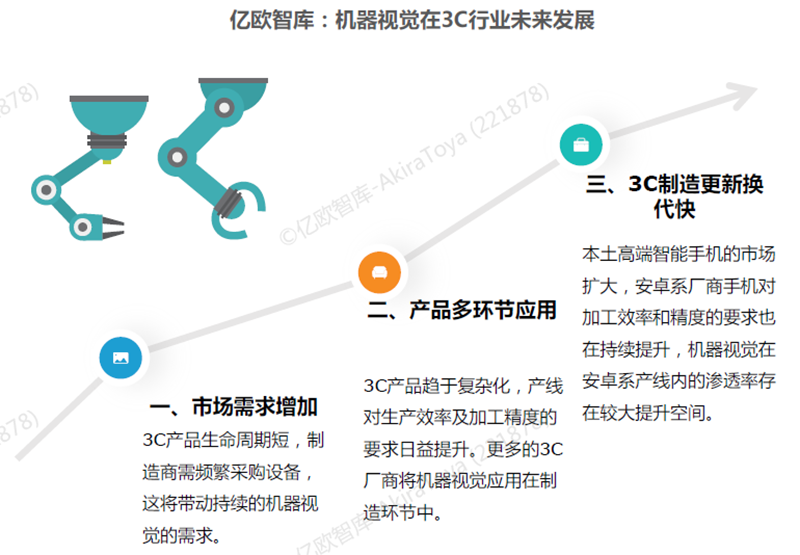

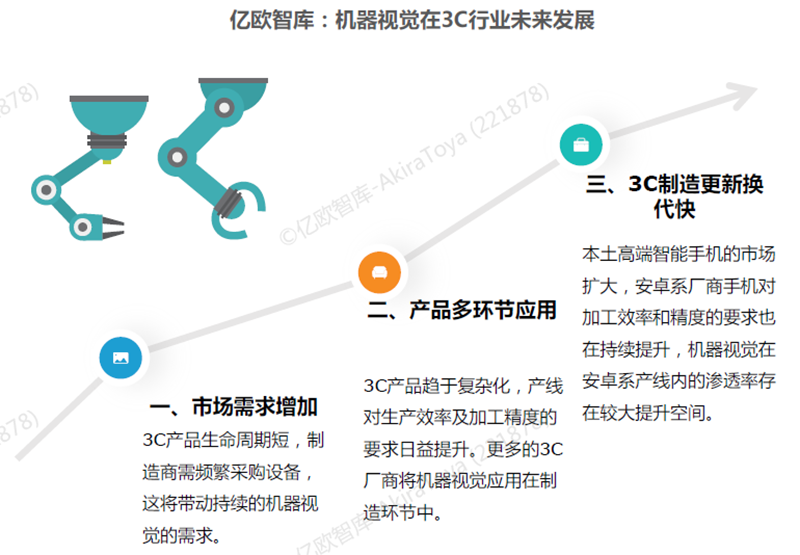

Track 1: As a benchmark for industrial visual industry applications, the 3C industry still faces technical difficulties that need to be overcome at this stage

The current global shift of the 3C electronics industry to developing countries, accompanied by the high precision and fast replacement of the 3C industry, is expected to promote the iteration of machine vision technology, extend application scenarios, and expand categories, which is expected to continue to promote the penetration rate of machine vision in China's 3C industry.

From the perspective of industry and product attributes, machine vision is the most mature application in the 3C electronics industry. The industry and product attributes of 3C electronics determine that the penetration rate of machine vision in this industry will be higher.

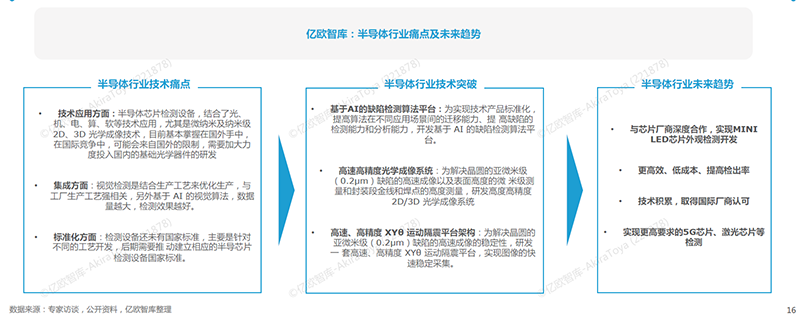

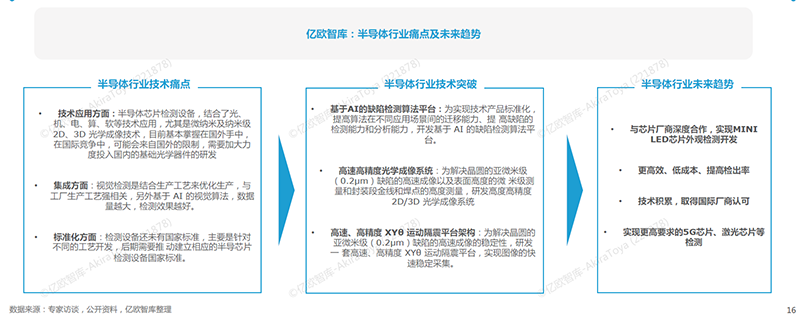

Track 2: The semiconductor industry will achieve full process technical support for machine vision in the future

The application of machine vision in the semiconductor industry is expected to achieve full process technical support for machine vision in the future. In 2019, the global semiconductor equipment market sales amounted to 57.6 billion US dollars, of which the Chinese market size was 12.9 billion US dollars, accounting for 22.4%. It is predicted that China's semiconductor investment will leap to the top in the world in the coming years.

The semiconductor industry has the characteristics of high integration and precision, and is one of the earliest large-scale applications of machine vision technology. The application of machine vision in the semiconductor industry involves the detection of semiconductor appearance defects, size, quantity, flatness, distance, positioning, calibration, solder quality, curvature, etc., especially in the entire process of wafer manufacturing, which requires the application of machine vision technology.

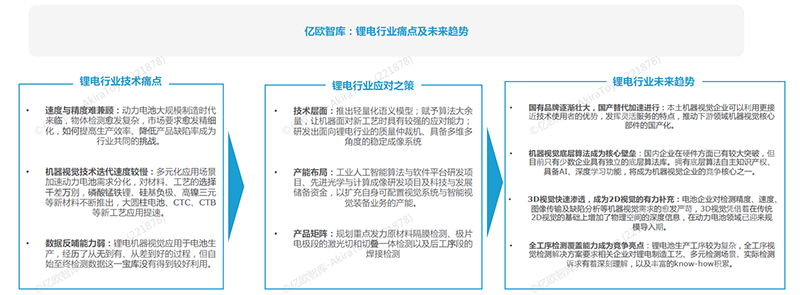

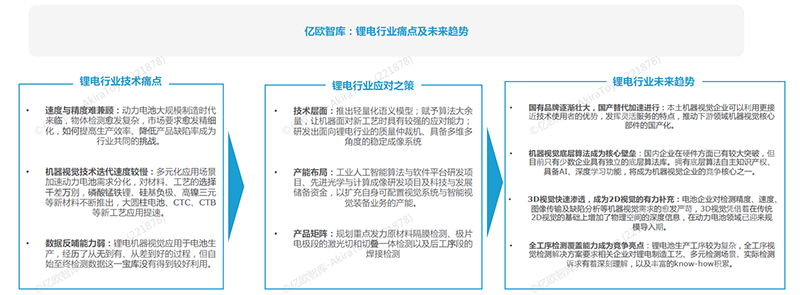

Track 3: Rapid development of the new energy vehicle industry, explosive demand in the lithium battery industry, and expansion of machine vision application scenarios

Machine vision is widely used in defect detection, size measurement, and localization of key processes in the sound field of power batteries. With the sustained high prosperity of the lithium battery industry and the booming development of new energy vehicles, the expansion of battery factories has brought about a surge in demand for machine vision equipment. At the same time, the complex process of lithium batteries also makes the application scenarios of machine vision more diverse. According to data from the National Bureau of Statistics, the production of lithium batteries in China has reached 23.26 billion units in 2021, a year-on-year increase of 23.4%. The rapid increase in lithium battery production capacity has driven the rapid development of machine vision, with a market size of 1.77 billion yuan in 2021 and a CAGR of 110% from 2019 to 2021.

Lithium ion batteries have complex application scenarios and production processes in machine vision, and multiple processes require machine vision inspection systems. With the continuous improvement of measurement requirements for battery cells, modules, and PACK, the conditions of the tested objects have become increasingly complex, and full line visual inspection has gradually become a standard configuration for power battery manufacturers.

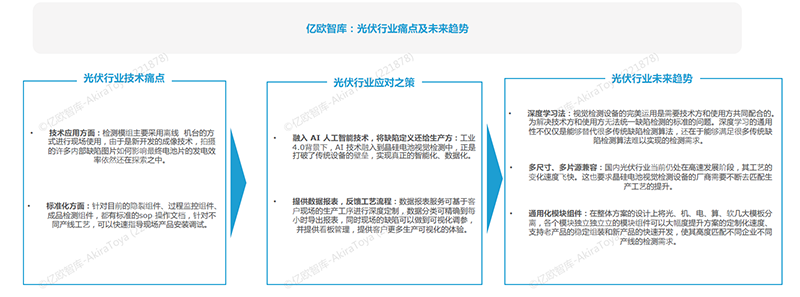

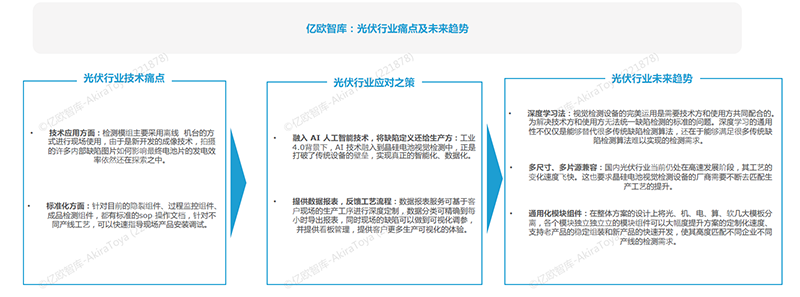

Track 4: The photovoltaic industry continues to accelerate its growth, and silicon wafer quality inspection is the key to ensuring the quality and development of solar cells

In 2021, China's solar cell production CAGR reached 35%, with a year-on-year growth rate of 42%, marking an accelerated growth period for the industry. During the same period, the application scale of machine vision in the photovoltaic industry has rapidly increased from 260 million yuan in 2019 to 650 million yuan in 2021, with a CAGR of 58%.

Throughout the entire production process of battery cells, quality monitoring of incoming silicon wafers, defect monitoring of process battery cells, and quality inspection of finished battery cells are the guarantees for producing high-quality battery cells. Each process section of the battery production quality monitoring system provides corresponding optical and mechanical visual modules (cameras, light sources, lenses, etc.), which can be quickly configured to provide high-quality visual imaging effects.

The Future Trends of Industrial Machine Vision

With the arrival of Industry 4.0, the demand for machine vision technology in industrial scenarios continues to drive the development of industrial machine vision technology. This includes the improvement of 3D technology requirements, the gradual dominance of domestic substitution, and the integration of fragmented scenes.

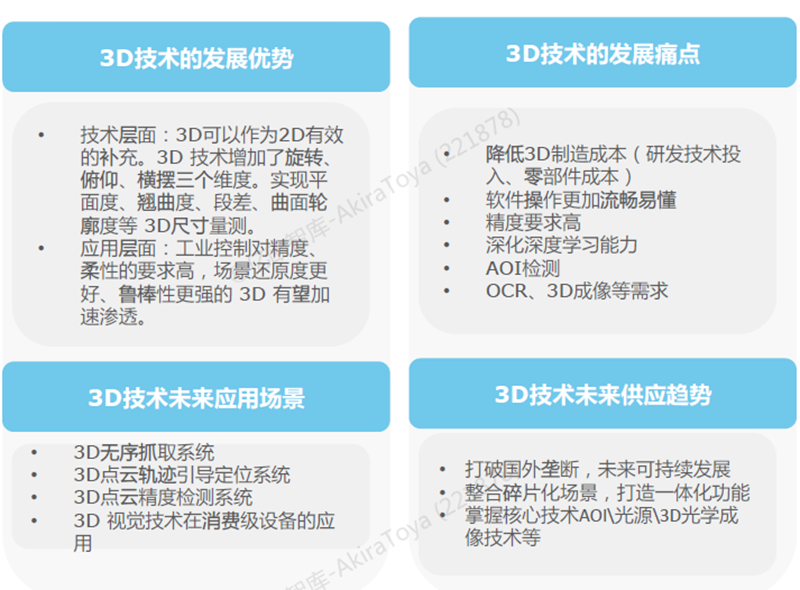

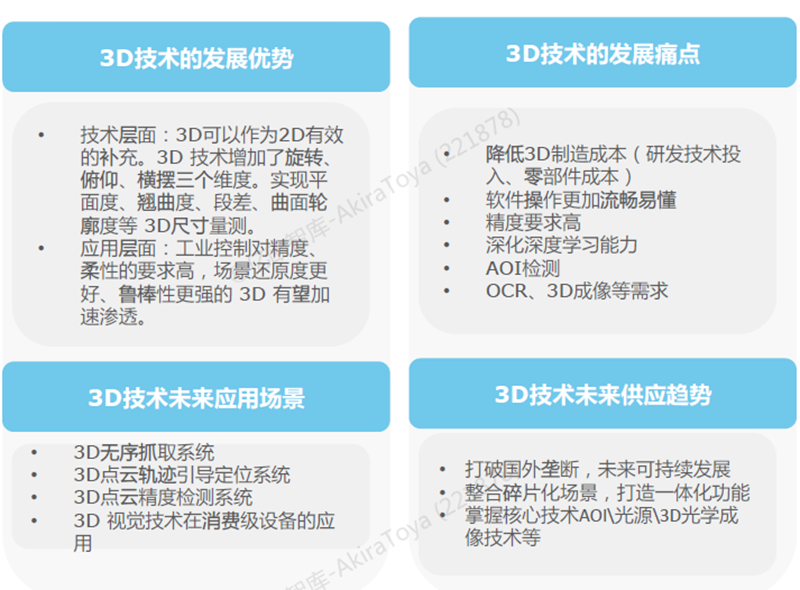

Trend 1: In the vast application scenarios, 3D technology will develop more maturely and widely

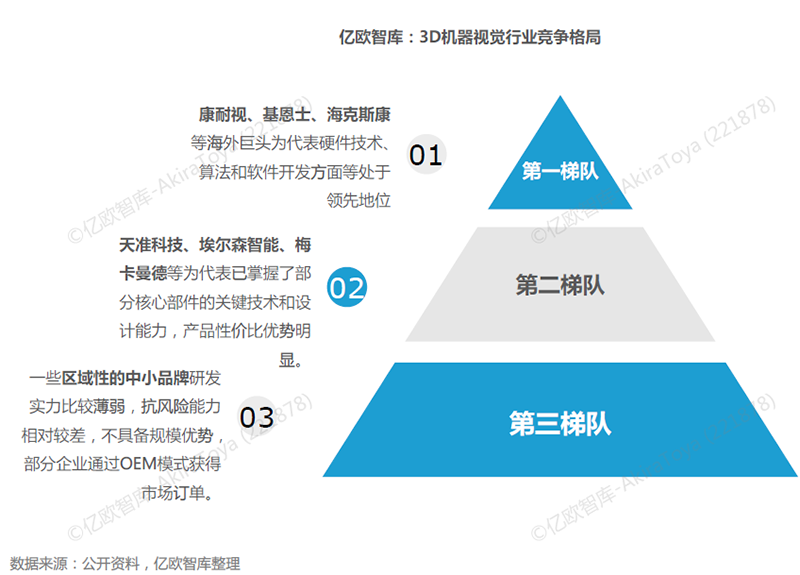

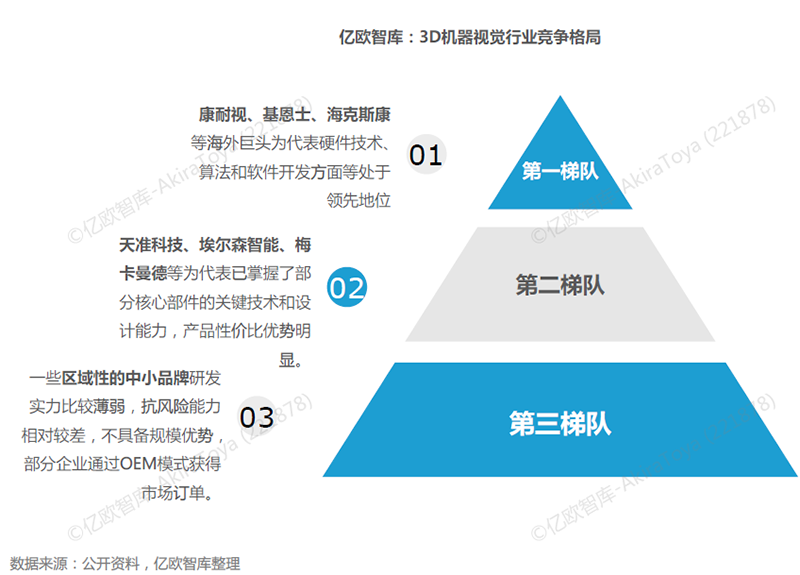

Along with the development of 2D vision, 3D technology is also on the rise. From the current trend, the development momentum of 3D machine vision is far greater than that of 2D. Although the current development of industrial machine vision is relatively mature, 3D technology is still in the early stages of development in China. Foreign companies and products are leading the domestic market in high-precision micro inspection and occupy a large share of the market. Domestic enterprises are gradually replacing foreign enterprises in hardware and software.

Trend 2: Localization substitution becomes the main theme, competition between domestic and foreign manufacturers further intensifies, and market structure is reconstructed

The current replacement rate of machine vision is 50%, but it is mostly limited to the field of 2D machine vision. In the future, with the cooperation and win-win of domestic brands, the product functions will be professional and the types will be refined, and the replacement rate will gradually increase. The industry will tend towards specialized division of labor, and autonomous visual platforms, visual systems, and equipment will work together to gradually surpass foreign brands and grow into the main force of visual technology in China's intelligent manufacturing industry.

The trend of domestic substitution in three major technological fields:

Trend 3: Integrating fragmented scenes and standardizing integrated equipment will be the next generation development direction of machine vision

With the gradual expansion of industrial automation, products under the intelligent manufacturing mode are produced in multiple varieties, small batches, and personalized ways. Enterprises are beginning to shift towards mass customization production, but machine vision technology can only recognize and classify a few products in automated production lines, making it difficult to meet fragmented scenarios. To address this situation, integrating fragmented scenarios and creating integrated devices will greatly promote the rapid integration of information technology and operational technology. At the same time, building a digital closed-loop throughout the entire process will also be one of the important measures.